You can rely on WESTFALIA products – the perfect connection!

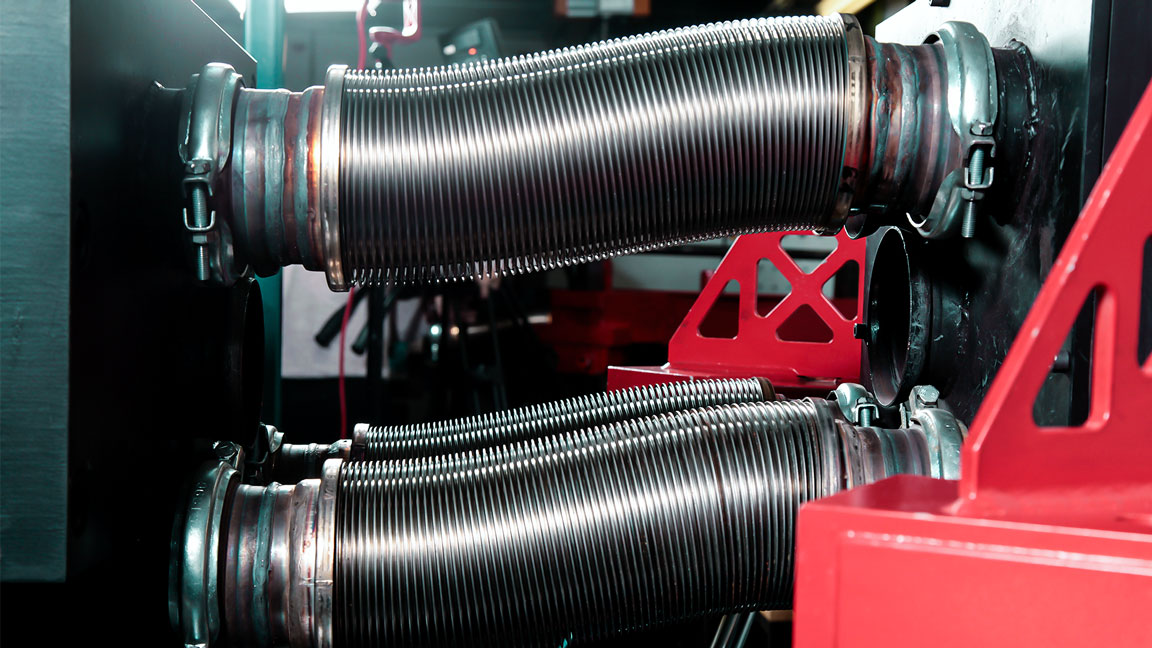

The reliability of decoupling elements is time and again inspected and proven by different in-house processes. Validation is carried out by simulation of real vehicle movements on hexapod and high-frequency shaker. Even under toughest conditions WESTFALIA prototypes and series parts give evidence of their reliability and fulfil three essential functions:

Data acquisition of movements and frequencies on test tracks that simulate typical road conditions and surfaces.

Analysis of data gained

Fatigue strength calculation

Low-cycle fatigue test to simulate road load situation

High-cycle fatigue test to check frequency behaviour