- Bending range up to 6 inches

- Small bending radius upt to 1 x D

- Lightweight design – wall thickness 1.5 mm available

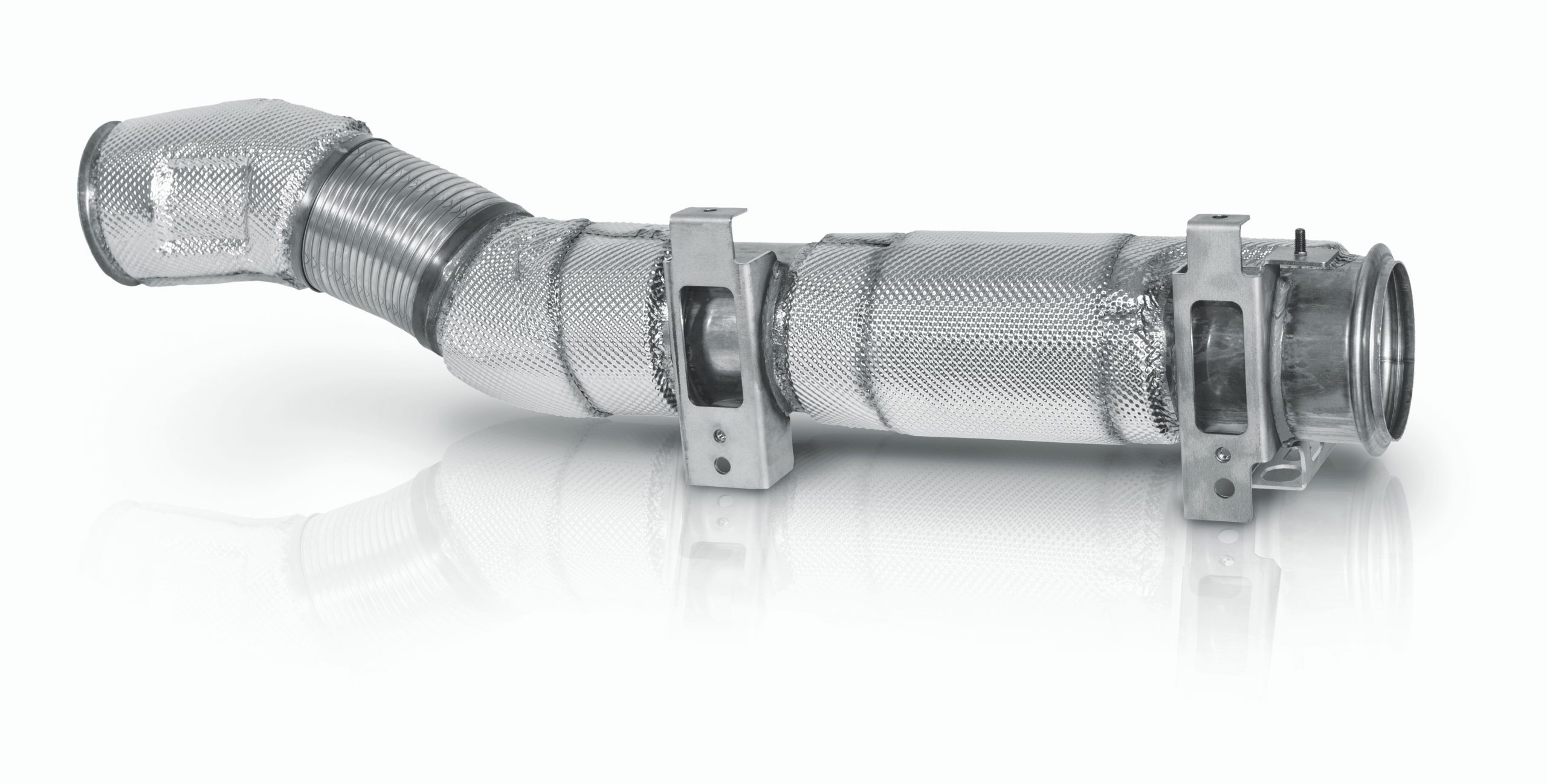

Stripwound hoses from WESTFALIA Metal Hoses are essential as decoupling element in exhaust systems of commercial vehicles. Apart from optimum compensation of movements they grant a perfect absorption of angular, lateral and torsional vibrations at highest temperatures. Stripwound hoses are made of stainless steel only.

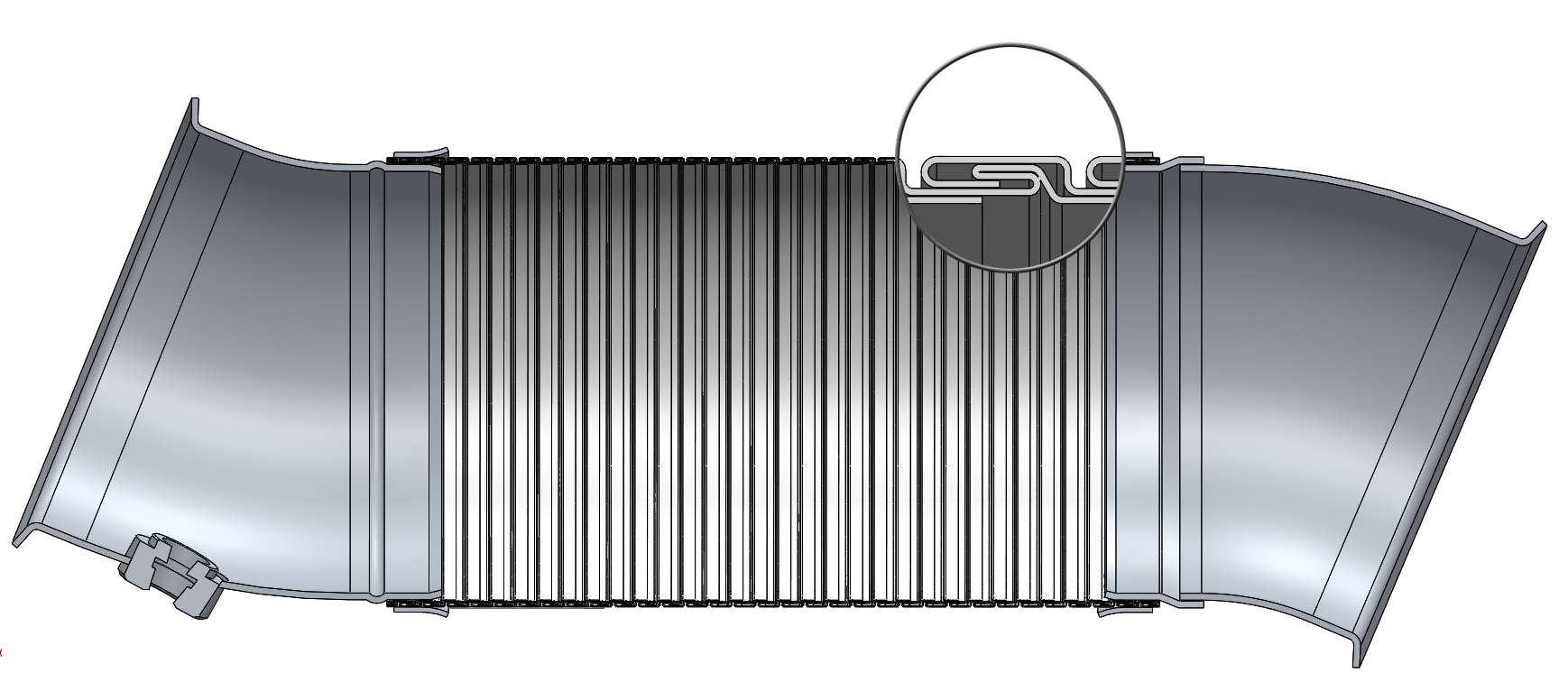

The optimum process set-up enables production of different diameters and lengths. The stripwound hose is manufactured in a fully-ingetrated Inline-Cutting-Process and combines forming, laser welding and cutting.

Even in the smallest installation area, WESTFALIA’s GTH exhaust line systems find the optimum space and guarantee the perfect connection between engine outlet and and exhaust aftertreatment inlet. For this purpose the Gastight Hoses GTH can be equipped with a vast variety of accessory parts:

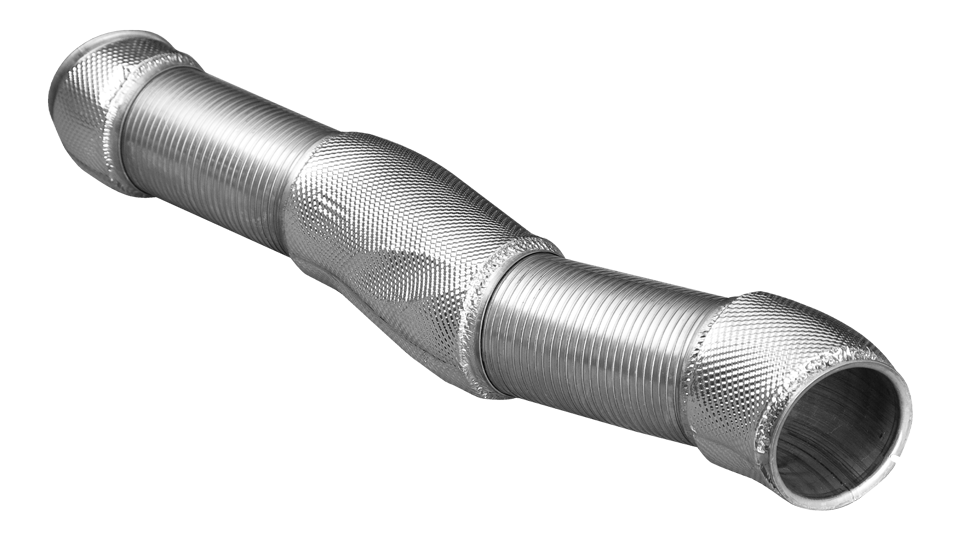

Stripwound Hose Type SSS

Stripwound Hose Type SSS Stripwound Hose Type SSS:

Round, double interlocked special profile with additional inner scale

Wickelschlauch Typ DSS:

Rund, double interlocked special profile with additional inner and outer scale

Downoad Data Sheet Type SSSFeel free to arrange an appointment with us.

Our team will be pleased to give you further information either in a personal meeting or via eMail.